The PVC resin extracts the pigment’s plasticizers completely into the shape of a plastic ink or solid film until fully cured. Know central, state, and federal legislation surrounding this method in all situations. If you use plastisol or inks dependent on water, they all contain chemicals strictly controlled for disposal. Some people even print and feel as good as traditional plastisol or better. Many have improved in terms of printability and handling over the last couple of years. Some function like plastisol, although others are not a substitution due to the new element. This includes low liquid traceability, does not dry on the monitor, and is extremely reflective and simple to treat.Ī modern form, which does not include PVC and phthalate. This form of ink comprises 100% solids, ensuring that there is no gassing off and zero degradation when written and cured. Many computer printers have been rendered using plastisol ink and are comfortable with their curing features and parameters. Today’s plastisols, the most widely used screen-printing ink, neither contain the minimal phthalates banned several years ago, nor harmful bone plumage or other hazardous substances used 40 years ago. Now let us look into some of the ink types available in the market.īoston based custom slide sandal maker has become $10 Million company using an online designer and unique growth marketing. The first time you have to burn the panel properly, but no consumables are washed down as the drain is forming because you need to burn it up again. The initial expense is high, but in the long run, it becomes much more economically sustainable. The newest trend in CTS technology is that it uses no consumables and achieves extremely high resolutions. However, if you need to burn the screen again, then you must spend double the ink cost as before. With the computer-to-screen trend, plastic screen backing has become obsolete.

Because it is convenient, and it makes the use of plastic films that can be recycled. In today’s times, the most common type of film is of inkjet type. Light, for screens, is like lead poisoning Exposure of displays and fine halftones tend to disappear.

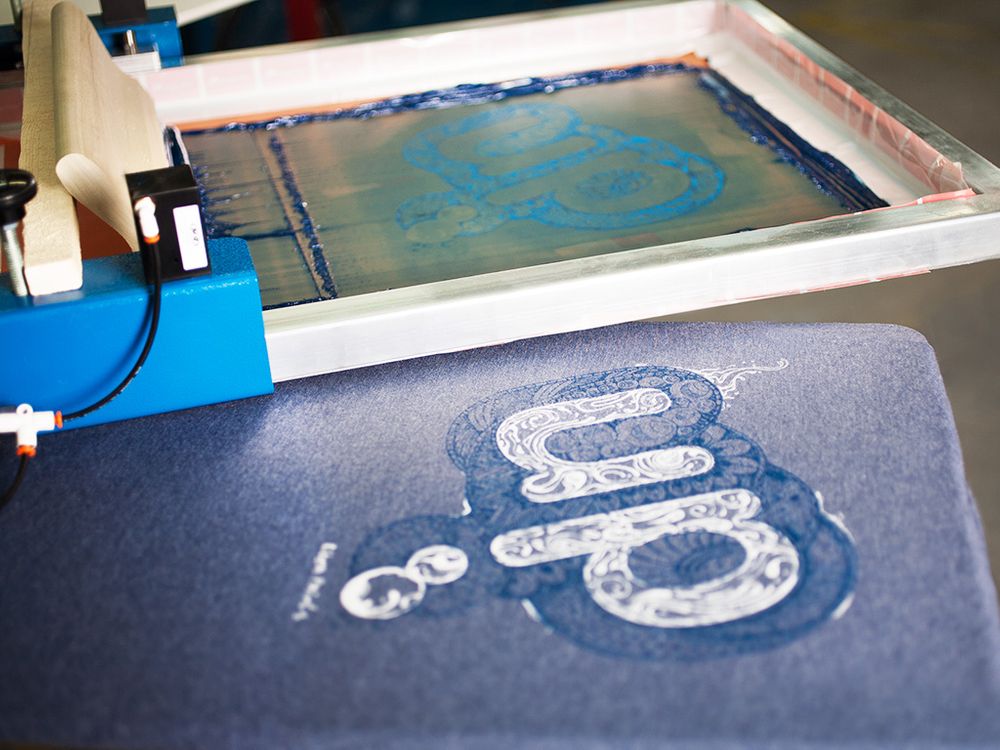

It is recommended to store screens light-safe environment. Besides, check your exposure times using a calculator either weekly or at least once a month. It is a process that uses more water and chemicals, and it is important to perform it right when you work for the first time. SEE ALSO: Top 14 Mistakes to Avoid When Starting a T-Shirt Business 2. That is to say, the least impact on the environment. When you make a screen for the first time, it will save money and save nature. Best 07 Eco-friendly and sustainable Screen Printing Practices: 1. The consumer’s perceptions are shifting, and so are we. When the world expands, renewable goods are rising when businesses begin to shift towards greener and more productive activities. Environmentally sustainable ideals touch the bottom line because many innovators have moved back to secure tax schemes instead of producing pricey eco-friendly goods. The customers set themselves the sight of finding the cheapest products and services in the past, especially in the last recession. The decorated clothing sector is subject to the demand of the market. It is possible to implement such practices with any screen printer while also being more sustainable. Screen printing is similar many processes can not be considered, such as sustainable or eco-friendly, but they can certainly be changed. Last Updated on: 29th November 2021, 12:04 pm

0 kommentar(er)

0 kommentar(er)